Hot Factory Rims Accessories Wholesale Replica Alloy Wheel Aluminum Car Wheels Rims

Description

Basic Info

| Model NO. | OYC001 |

| Type | Rim |

| Drive Wheel | 4WD |

| Wheel Hub Diameter | 9-26inch |

| Finishing | Paniting/Machined/Colorful Chrome/Polish/Brushed |

| Wheel Accessories | Wheel Cover |

| Spoke Type | Equal Diameter Spoke |

| Certification | ISO, VIA, TUV, DOT |

| Wheel Hub Brand | OEM |

| Terms | Fob, CIF, CFR |

| Sample | From Stock Choice |

| Delivery | 30days |

| Commodity | 18inch 20inch 23inch Replica Wholesale Car Accesso |

| Goods | Wheels Rims for Audi for BMW for Amg for Toyota |

| Transport Package | Circle Ring, Foam, Plastic, Carton |

| Specification | 1570 1680 1790 1880 1980 2090 2295 2190 2290 2310 |

| Trademark | OEM brand |

| Origin | China |

| HS Code | 870870 |

| Production Capacity | 3000000/Year |

Packaging & Delivery

Package size per unit product 48.00cm * 48.00cm * 28.00cm Gross weight per unit product 10.000kgProduct Description

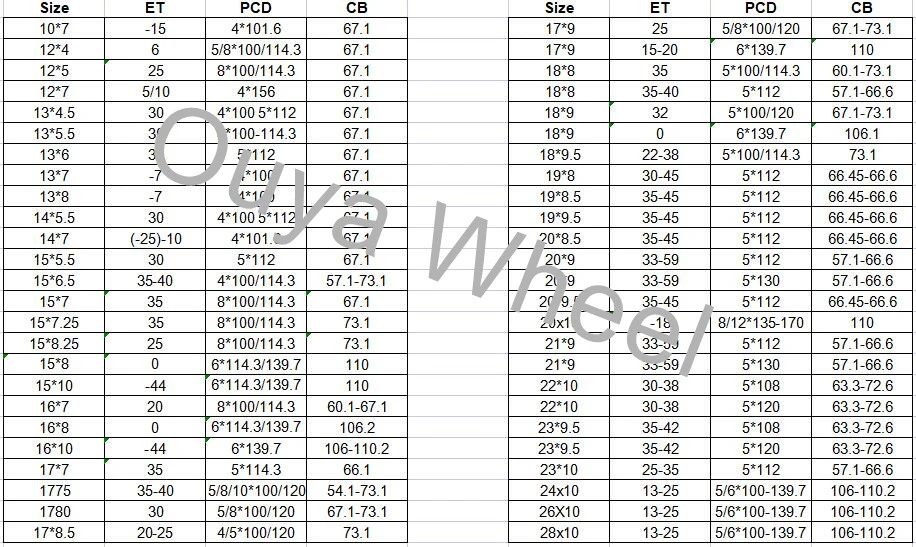

| size | OFF-SET | PCD | CB |

| Customizable | Customizable | Customizable | Customizable |

18inch 20inch 23inch wholesale replica alloy wheel Aluminum Car Wheel Rims Car Accessories for RS3_SportbackCASTING WHEEL

Melt-Cast-Heat treatment-Maching-Painting-Packing

X-Ray test-Detecting shrinkage, air bubbles, dross, ect

Mechanical Proterties-Improve the tensile strength, elongation and hardness

Parameter and Test-Main parameter and testing to be done followed

Corrosion resistance-Finished varnish requires 448 hours of neutral salt spray test

Protection-Hardness carton and foam protection

FORGED WHEEL

FORGED MATERIAL-T6061 is one of the high quality aluminum alloy products after heating process and pre-extending process, it has the properties of good processing, great welding and chrome-plating, good corrosion resistance, high strength and great resistance to deformation, tight structure, flawlessness and it is also very easy to polish, powder and affiliate other needed material on surfaces of Mg-Al 6061 made products. 6061-T6 comprises of Si, Cu, Mn, Mg, Zn, Fe, Ti, Cr and Ni. All bars are with homogenization and their structures are more even and tighter.

FLOW FORMING WHEEL

FLOW FORMING is also called casting plus flow forming process. It is a derivation of forging technology.

New mould aprroved if you have wonderful ideas.

INTERNATIONAL CERTIFICATION,all products are of ISO9001, VIA, JWL, SFI

Shaoxing Ouya Trade Co. , Ltd

OUYA establishes its brand in October, 2014. Relying on advanced production technology equipment and high-quality production management talents, with world first-class maufacturing and detecting equipment, including continous-type heat treatment, automatic spraying lines, spectrum analyzers, X-ray , achined , three-coordinate measuring machines, rotating-bending machines, radical rolling fatigue testing machines, impact testing machines, salt fog testing machined and universal materials testers, our products have passed international certification ISO9001, VIA, JWL, SFI, TUV. Adhering to the principle of quality as the foundation, innovation as the guide, and customer-centered, we are committed to the concept of the best quality, best service and most competitive price. We have established long-term friendly relationships with customers in many countries and regions such as the United Kingdom, Bulgaria, the United States, Canada, Australia, New Zealand, Chile, Africa, and South Africa.

VARIOUS PRODUCTS

Wheel weigh significantly less than a same spec . Economically,Wheel offers fuel savings and increased fuel mileage.

Stronger

It allows for a stronger wheel.They create a 20-30% increase in tensile strength.

Greater Shock Resistance

This greater shock resistance is a key benefit of the stronger, as it adds to the increased stress capacity formed by the stretching and compressing of the original cast wheel.

Higher Load Rating

It increases the tensile strength of a wheel design, this also yields a higher load rating.

Increased Elongation

Elongation is described as the limit a wheel is able to flex before reaching breaking point.Technology provides an increase in elongation, both in the barrel and rear flange area which significantly increases the shock resistance in a potential hazard.

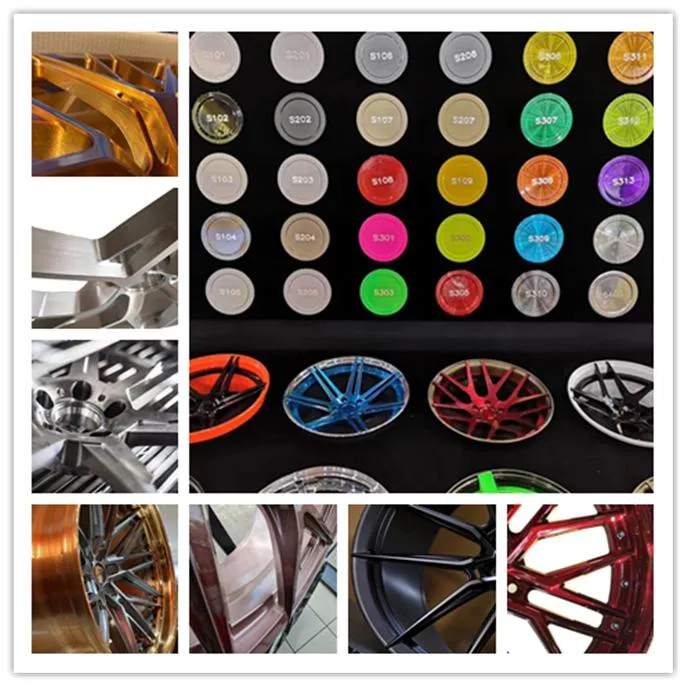

VARIOUS FINISHING TO MAKE YOUR CAR SHINING ONE

Normal painting/Machined/Hyper/Brushed/Colorful Chrome,ect.

PACKAGE STANDARD:Hardness carton and foam protection,also rings and extra protection for the lip

DELIVERY:Production takes about 30days;Stock 10days around

Our Contact